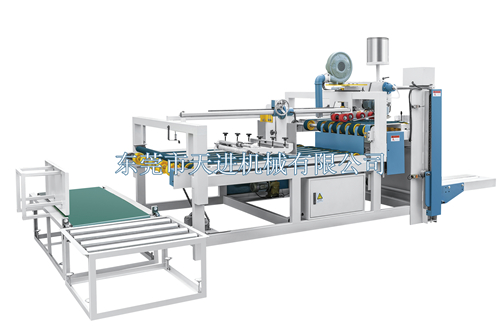

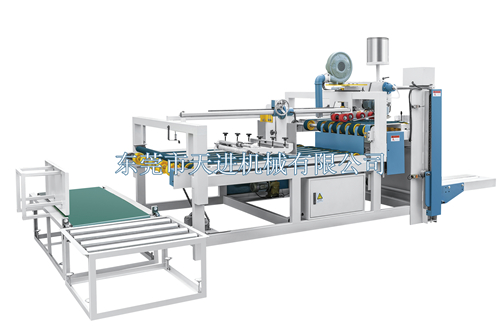

Semi-automatic carton gluing machine: It is the last process equipment for making carton, mainly used for gluing single corrugated cardboard to meet the requirements of multi-variety, small and medium batch production, and adapt to the packaging needs of export products such as food and cotton. It is currently the most ideal carton equipment. This machine has the advantages of high production efficiency, low labor intensity, simple operation, stable performance and reliable operation. It is the molding equipment for the packaging carton industry.

Main parts of semi-automatic box gluer TJ-HA

● Gear reducer adopts Taiwan gear reducer

● Taiwan Tende button switch, travel switch, terminal block

● Taiwan Yangming photoelectric switch, counter, Taiwan Shihlin contactor

● Taiwan conveyor belt

● The whole glue head group adopts imported materials for precision processing, wear resistance and corrosion resistance

Function

● Automatic counting at the back stage, the number of finished products (1-99 sheets) can be stacked and sent to the end of the conveyor according to the set number, which is convenient for bundling

● The fan assists the drying function to speed up the gluing of cartons and reduce the production of defective products

● It only takes two people to glue the semi-finished products to the finished products, which is simple and convenient to operate and reduce wages

● The paper feeding part counts automatically, stacks into bundles and automatically sends them out for bundling, reducing the number of people counting cartons and reducing wages

● The middle section additional punching function effectively avoids the phenomenon of scissor clamping of cartons

Parameters

|

Scope of application

|

Mechanical specifications

|

|

Maximum size (length + width) Maⅹ(L+W)ⅹ2

|

2800mm

|

Applicable horsepower Power

|

5HP

|

|

Minimum size (length + width) Min(L+W)ⅹ2

|

340mm

|

Mechanical length Length

|

4500mm

|

|

Maximum size (length + width) Min(L+W)ⅹ2

|

1515mm

|

Mechanical Width

|

2100mm

|

|

Minimum size (length + width) Min(L+W)ⅹ2

|

240mm

|

Mechanical Weight

|

2000kgs

|

|

Feed height High of feeder

|

900mm

|

Mechanical speed Speed

|

40M/min

|